HISTORY

Lynda studied the traditional method of lost-wax casting at Central Washington University. In her graduate studies at the University of Washington, Lynda produced large-scale work that employed metal-fabrication techniques and sand-casting processes.

In 1982, Lynda co-established Penta Studios in Seattle’s South Lake Union neighborhood. The studio provided space for five women who worked with metal as a primary medium. Lynda fabricated sculpture for herself and other artists in bronze, aluminum, and stainless steel.

In 1985, as head of Webster University’s sculpture program, Lynda taught the complete sculpture curriculum including foundry and metal-fabrication. She also produced the following series during her years with Webster: Architecture of Earth, Sphere / Spiral, and Vessel / Tomb.

In 1992, Lynda returned to the Pacific Northwest as a visiting artist at the University of Washington. She also began The Atomic West series which incorporated scientific instruments and laboratory glass.

In 1997, Lynda established her studio in Seattle’s Ballard neighborhood where she created the Fossil & Ash, Mining the Ellipse, Mapping Strata, Contemplating the Stupa, and Charting Geologic Time series. The work is smaller in scale and incorporates metals with fossils, hydrostone, cement, sea glass, and cast glass as component parts.

Lynda also formally expanded her business, Rockwood Enterprises LLC, to include sculpture conservation and consulting services from 1997 through 2014.

MATERIALS & TECHNIQUES

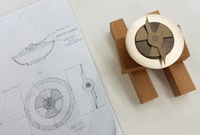

- Concept drawings and scale model

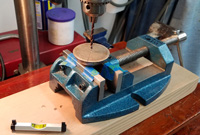

- Making tea bowl pattern

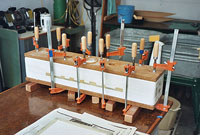

- Tea bowl pattern and two-part mold

- Bronze casting method & tools

- Melting silicon bronze & two-part mold

- Tea bowls after casting in set-sand

- Cast silicon bronze shells & tea bowls

- Cutting out Antarctica patterns

- Patterns on orbit-sanded bronze sheet

- Cutting out pattern on the band saw

- Very slowly cutting out Antarctica

- Filing edges of architectural forms

- Architectural patterns & cutout forms

- Silicon bronze orbit-sanded

- Bronze shells fitted for welding

- TIG welding bronze shell forms

- Orbit-sanding weld areas on Antarctica

- Cutting lines for longitude & latitude

- Antarctica after sand-blasting

- Peeling back protective mask

- Pattern ready for sand-blasting

- Peeling back mask after sand-blasting

- Hand-cutting areas for sand-blasting

- Bronze surface after sand-blasting

- Drilling tea bowl after welding

- Drawing of atomic compass & pattern

- Drilling hole in bottom of tea bowl

- Tea bowls set to weld screws in place

- Threading bronze to attach to plate

- Placement of tea bowls & lotus disks

- All bronze works ready for patina

- Polar Paradox compass before patina

- Polar Meltdown in patina bath

- Polar Meltdown after patina

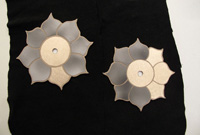

- 3 bronze shapes of the lotus form

- All Strata Time Table parts after patina

- Casting hydrostone

- Rubber mold & support mold

- Bronze sheet cast inside mold

- Rubber mold-making

- Rubber mold & foam pattern

- Wet sanding hydrostone casting

- Sea urchin pattern and box

- Two-part set-sand mold

- Bronze set-sand casting

- Silicon bronze in prep for TIG welding

- Pattern & fitting

- Bronze shell forms in prep for welding

- Pattern applied to bronze sheet

- Fitting tack welding part to pattern

- Cutting Caspian & Black Sea shapes

- Designs cut on sanded bronze

- Sand-blasted designs

- Green / brown patina of Puget Sound

- Cast hydrostone with ash & shell

- Making shell patterns for sand casting

- Working with stupa concepts

- Tea bowl pattern and two-part mold

- Shell set-sand molds ready to soot

- Sooted set-sand molds ready to cast

- Silicon bronze set-sand casting

- Tea bowls after casting in set-sand

- Bronze spheres, shells & tea bowls

- Drawing & pattern for sand-blasting

- Lotus petal pattern etched with sand

- Bronze lotus design ready for patina

- Bronze sheet, rod & cast parts

- Welding & machine screw fabrication

- Threading of bronze shell legs

- Final fitting of all component parts

- Finish patinas on all bronze parts

- Hydrostone & bronze parts assembled